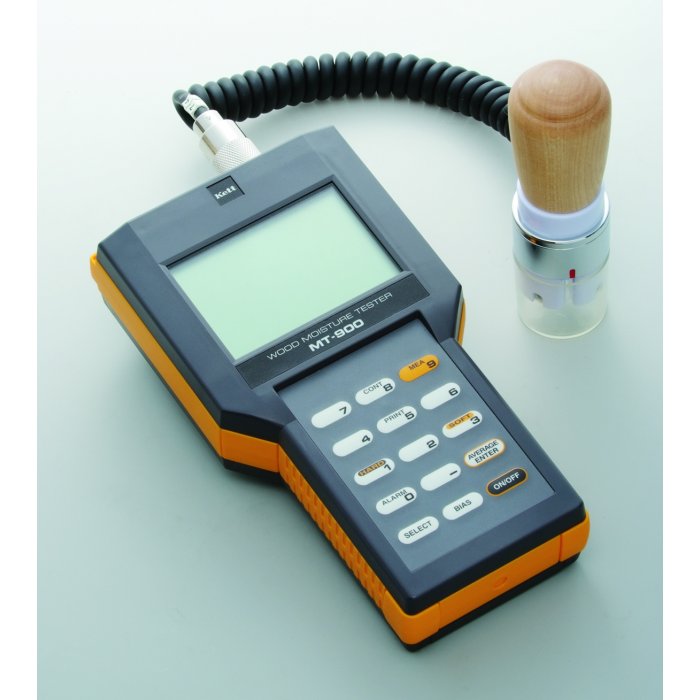

Wood Moisture Tester

The wood moisture tester is a crucial tool in various industries, including woodworking, construction, and forestry. It is used to measure the moisture content of wood, which is essential in determining its quality, durability, and suitability for different applications. In this article, we will delve into the world of wood moisture testers, exploring their types, features, and importance in the industry.

Types of Wood Moisture Testers

There are several types of wood moisture testers available, each with its unique features and advantages. The most common types include:

- Pin-type moisture meters: These meters use two pins to penetrate the wood and measure the electrical resistance between them. The resistance is directly related to the moisture content of the wood.

- Pinless moisture meters: These meters use a non-invasive technique to measure the moisture content of wood. They emit a low-frequency electromagnetic field that penetrates the wood, and the moisture content is calculated based on the field’s interaction with the wood.

- Radio frequency (RF) moisture meters: These meters use RF waves to measure the moisture content of wood. They are non-invasive and can measure the moisture content of wood at various depths.

Features of Wood Moisture Testers

Wood moisture testers come with various features that make them useful in different applications. Some of the key features include:

Accuracy: A good wood moisture tester should have high accuracy, typically ±1-2% moisture content. This ensures that the readings are reliable and consistent.

Easy to use: The tester should be easy to use, with a simple and intuitive interface. This allows users to quickly and easily measure the moisture content of wood.

Durable: Wood moisture testers should be durable and able to withstand rough handling and harsh environments. This ensures that they remain accurate and functional over time.

Other features of wood moisture testers include data logging, Bluetooth connectivity, and alarm functions. These features allow users to track changes in moisture content over time, transfer data to computers or mobile devices, and receive alerts when the moisture content exceeds a certain threshold.

| Moisture Meter Type | Accuracy | Ease of Use | Durability |

|---|---|---|---|

| Pin-type | ±1-2% | Easy | High |

| Pinless | ±1-2% | Easy | High |

| RF | ±1-2% | Easy | High |

Importance of Wood Moisture Testers

Wood moisture testers play a critical role in various industries, including woodworking, construction, and forestry. They help to:

Determine wood quality: By measuring the moisture content of wood, testers can help determine its quality and suitability for different applications.

Prevent damage: Excessive moisture content can lead to damage, warping, or rotting of wood. Wood moisture testers help to identify potential problems before they occur.

Optimize wood processing: By measuring the moisture content of wood, testers can help optimize wood processing operations, such as drying, gluing, and finishing.

In addition, wood moisture testers are used in various other applications, including:

- Wood flooring installation: To ensure that the wood flooring is properly acclimated to the environment.

- Woodworking: To measure the moisture content of wood before and after processing.

- Forestry: To measure the moisture content of wood in trees, helping to determine their quality and suitability for harvesting.

Future Implications

The use of wood moisture testers is expected to continue growing in the future, driven by increasing demand for high-quality wood products and the need to optimize wood processing operations. Advances in technology, such as the development of more accurate and non-invasive testing methods, are likely to further expand the use of wood moisture testers in various industries.

Additionally, the increasing focus on sustainability and environmental protection is likely to drive the adoption of wood moisture testers, as they help to reduce waste and optimize the use of wood resources.

What is the importance of calibrating a wood moisture tester?

+Calibrating a wood moisture tester is essential to ensure accuracy and reliability. Calibration helps to adjust the tester to the specific type of wood being tested, taking into account factors such as density and moisture content.

Can wood moisture testers be used to measure the moisture content of other materials?

+While wood moisture testers are specifically designed to measure the moisture content of wood, some models can be used to measure the moisture content of other materials, such as drywall, concrete, or plaster. However, it’s essential to consult the manufacturer’s instructions and ensure that the tester is calibrated for the specific material being tested.

How often should a wood moisture tester be calibrated?

+The frequency of calibration depends on the type of tester and the frequency of use. As a general rule, wood moisture testers should be calibrated at least once a year, or as recommended by the manufacturer. Additionally, testers should be calibrated whenever they are dropped, exposed to extreme temperatures, or used in harsh environments.