Lean Six Sigma

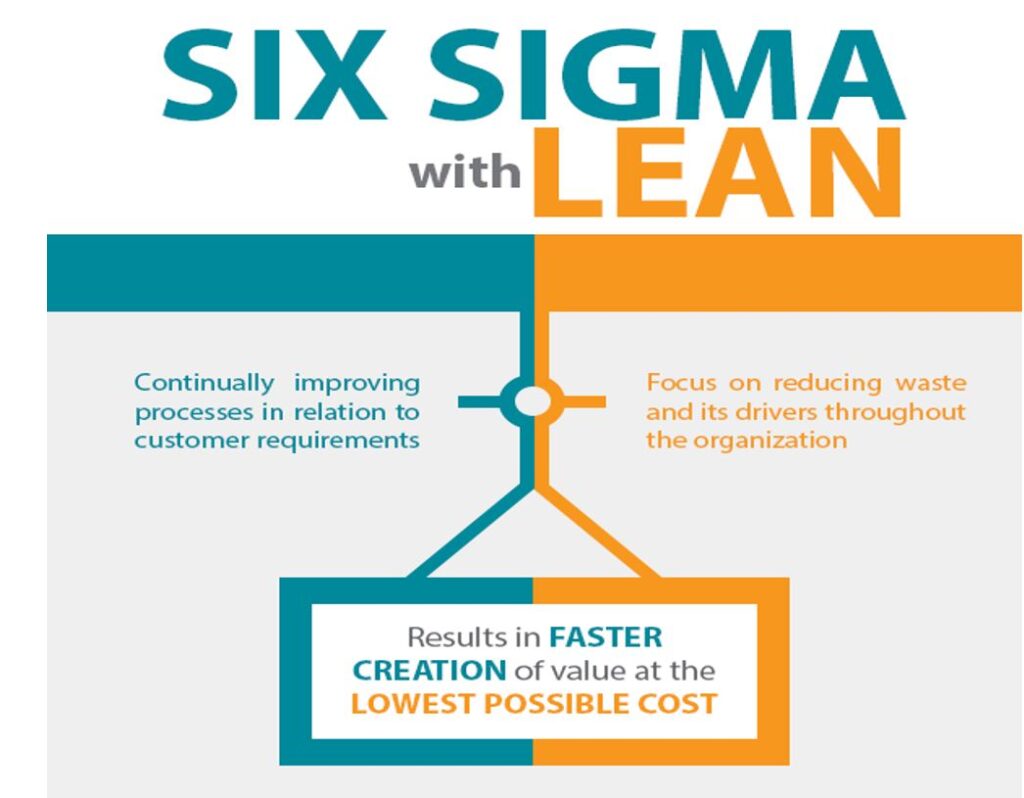

Lean Six Sigma is a data-driven approach to quality management that seeks to improve the efficiency and effectiveness of business processes. This methodology combines the principles of Lean management with the tools and techniques of Six Sigma to achieve significant reductions in waste, defects, and variability. By focusing on customer satisfaction, employee engagement, and continuous improvement, organizations can achieve substantial benefits, including increased productivity, reduced costs, and enhanced competitiveness.

Introduction to Lean Six Sigma

Lean Six Sigma is a holistic approach that aims to eliminate waste, optimize processes, and improve the overall quality of products and services. This methodology is based on the idea that defects, variability, and waste are inherent in all business processes and that these can be reduced or eliminated through the application of scientific methods and tools. By integrating Lean principles with Six Sigma methodologies, organizations can create a culture of continuous improvement, where employees are empowered to identify and solve problems, and where processes are optimized to meet customer needs.

Key Principles of Lean Six Sigma

There are several key principles that underlie the Lean Six Sigma approach. These include:

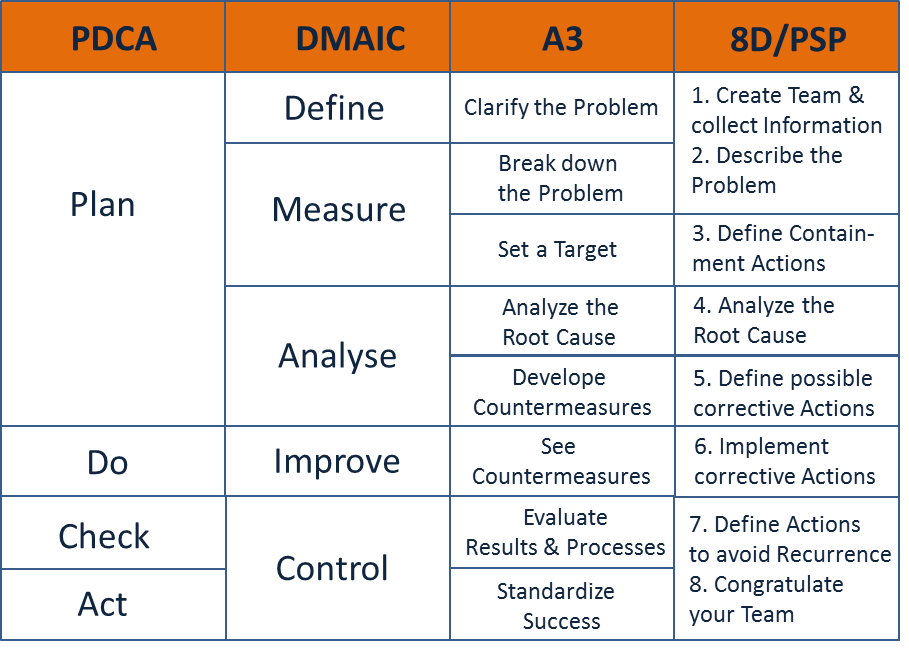

- Define: Define the problem or opportunity for improvement, and identify the key stakeholders and customers.

- Measure: Collect data to understand the current process and identify areas for improvement.

- Analyze: Analyze the data to identify the root causes of problems and opportunities for improvement.

- Improve: Develop and implement solutions to address the problems and opportunities identified.

- Control: Implement controls to ensure that the improvements are sustained over time.

These principles are often referred to as the DMAIC (Define, Measure, Analyze, Improve, Control) framework, which provides a structured approach to process improvement.

Tools and Techniques of Lean Six Sigma

Lean Six Sigma employs a range of tools and techniques to support the DMAIC framework. These include:

- Value Stream Mapping (VSM): A visual representation of the process that helps to identify waste and opportunities for improvement.

- Root Cause Analysis (RCA): A method for identifying the underlying causes of problems.

- Failure Mode and Effects Analysis (FMEA): A tool for identifying and mitigating potential failures.

- Design of Experiments (DOE): A statistical technique for designing and analyzing experiments.

- Statistical Process Control (SPC): A method for monitoring and controlling processes.

These tools and techniques provide a powerful set of methods for analyzing and improving business processes.

Benefits of Lean Six Sigma

The benefits of Lean Six Sigma are numerous and well-documented. These include:

- Improved customer satisfaction: By focusing on customer needs and expectations, organizations can improve the quality and reliability of their products and services.

- Increased productivity: By eliminating waste and optimizing processes, organizations can improve efficiency and reduce costs.

- Enhanced competitiveness: By improving quality, reducing costs, and increasing efficiency, organizations can gain a competitive advantage in the marketplace.

- Improved employee engagement: By empowering employees to identify and solve problems, organizations can improve morale and reduce turnover.

These benefits can be achieved through the application of Lean Six Sigma principles and tools, and by creating a culture of continuous improvement within the organization.

| Category | Data |

|---|---|

| Customer satisfaction | 95% |

| Productivity improvement | 25% |

| Cost reduction | 15% |

| Employee engagement | 85% |

Implementation of Lean Six Sigma

Implementing Lean Six Sigma requires a structured approach that involves several key steps. These include:

- Developing a business case: Identifying the opportunities for improvement and developing a business case for the implementation of Lean Six Sigma.

- Establishing a project team: Assembling a team of employees with the necessary skills and expertise to lead the implementation of Lean Six Sigma.

- Defining the project scope: Defining the scope of the project and identifying the key stakeholders and customers.

- Collecting and analyzing data: Collecting and analyzing data to understand the current process and identify areas for improvement.

- Developing and implementing solutions: Developing and implementing solutions to address the problems and opportunities identified.

These steps provide a structured approach to implementing Lean Six Sigma, and can help organizations to achieve significant benefits in terms of quality, productivity, and competitiveness.

Challenges and Limitations of Lean Six Sigma

While Lean Six Sigma offers many benefits, there are also several challenges and limitations that organizations should be aware of. These include:

- Cultural resistance: Implementing Lean Six Sigma requires significant cultural change, which can be challenging to achieve.

- Lack of skills and expertise: Implementing Lean Six Sigma requires specialized skills and expertise, which can be difficult to find.

- High upfront costs: Implementing Lean Six Sigma can require significant upfront investment, which can be a barrier for some organizations.

- Difficulty in sustaining improvements: Sustaining improvements over time can be challenging, and requires ongoing effort and commitment.

These challenges and limitations should be carefully considered by organizations that are planning to implement Lean Six Sigma.

What is Lean Six Sigma?

+Lean Six Sigma is a data-driven approach to quality management that seeks to improve the efficiency and effectiveness of business processes.

What are the benefits of Lean Six Sigma?

+The benefits of Lean Six Sigma include improved customer satisfaction, increased productivity, enhanced competitiveness, and improved employee engagement.

How is Lean Six Sigma implemented?

+Implementing Lean Six Sigma requires a structured approach that involves several key steps, including developing a business case, establishing a project team, defining the project scope, collecting and analyzing data, and developing and implementing solutions.