Gauge Steel Thickness Explained

Gauge steel thickness is a critical factor in various industries, including construction, manufacturing, and engineering. The term "gauge" refers to the thickness of a steel sheet or plate, which is measured in inches or millimeters. Understanding the concept of gauge steel thickness is essential for designers, engineers, and technicians to ensure the structural integrity and durability of their projects.

Introduction to Gauge Steel Thickness

The gauge system is a traditional method of measuring the thickness of steel sheets and plates. It is based on the Stubs Iron Wire Gauge, which was developed in the 19th century. The system assigns a gauge number to each thickness, with lower gauge numbers indicating thicker steel and higher gauge numbers indicating thinner steel. For example, a 10-gauge steel sheet is thicker than a 20-gauge steel sheet.

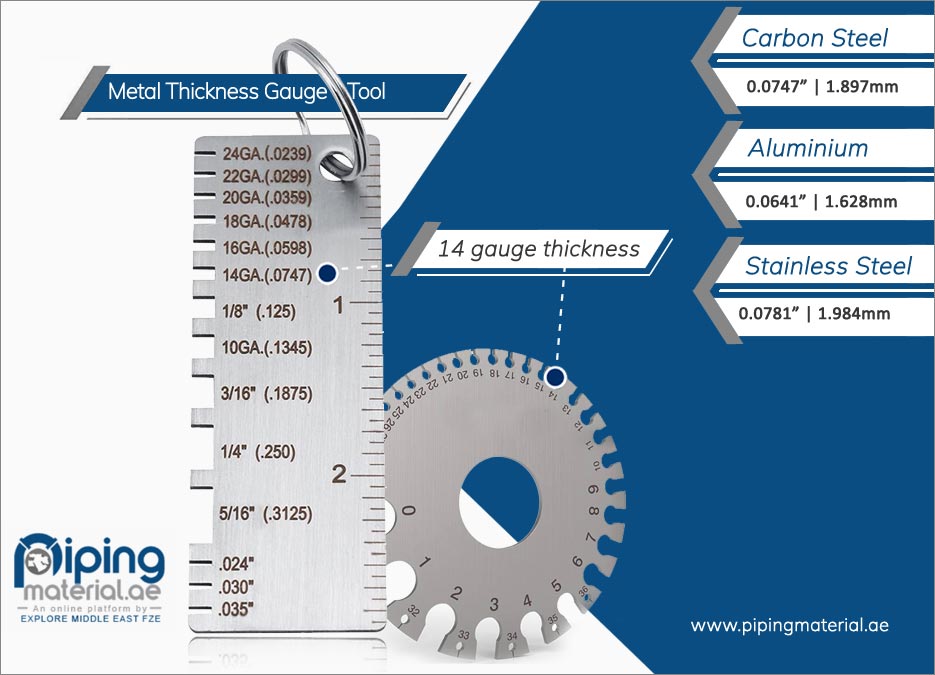

Gauge Steel Thickness Chart

To better understand the gauge system, it is helpful to refer to a gauge steel thickness chart. The chart lists the gauge numbers and their corresponding thicknesses in inches and millimeters. Here is a sample chart:

| Gauge Number | Thickness (inches) | Thickness (mm) |

|---|---|---|

| 10 | 0.1345 | 3.416 |

| 12 | 0.1046 | 2.657 |

| 14 | 0.0785 | 1.994 |

| 16 | 0.0598 | 1.519 |

| 18 | 0.0472 | 1.199 |

| 20 | 0.0359 | 0.912 |

As shown in the chart, the thickness of steel sheets and plates decreases as the gauge number increases. This is important to consider when designing and building structures, as the thickness of the steel can affect its strength, durability, and overall performance.

Factors Affecting Gauge Steel Thickness

Several factors can affect the gauge steel thickness, including the type of steel, the manufacturing process, and the intended application. For example, stainless steel and aluminum sheets may have different gauge thicknesses due to their unique properties and uses. Additionally, the hot-rolled and cold-rolled manufacturing processes can result in different thicknesses and surface finishes.

Applications of Gauge Steel Thickness

Gauge steel thickness is critical in various industries, including construction, manufacturing, and engineering. Some common applications of gauge steel thickness include:

- Building construction: Steel sheets and plates are used in building frames, roofs, and walls, where thickness is crucial for structural integrity and durability.

- Automotive manufacturing: Steel sheets and plates are used in vehicle bodies, chassis, and engine components, where thickness affects performance, safety, and fuel efficiency.

- Aerospace engineering: Steel sheets and plates are used in aircraft and spacecraft structures, where thickness is critical for weight reduction, strength, and durability.

Conclusion

In conclusion, gauge steel thickness is a critical factor in various industries, and understanding the concept is essential for designers, engineers, and technicians. By referring to a gauge steel thickness chart and considering the factors that affect thickness, professionals can ensure the structural integrity and durability of their projects. Whether in construction, manufacturing, or engineering, gauge steel thickness plays a vital role in achieving optimal performance, safety, and efficiency.

What is the difference between gauge and thickness in steel sheets?

+The gauge number refers to the thickness of a steel sheet, with lower gauge numbers indicating thicker steel and higher gauge numbers indicating thinner steel. Thickness, on the other hand, refers to the actual measurement of the steel sheet in inches or millimeters.

How do I determine the gauge steel thickness for my project?

+To determine the gauge steel thickness for your project, consider the specific requirements, including the type of steel, manufacturing process, and intended application. Refer to a gauge steel thickness chart and consult with industry experts or manufacturers to ensure the steel sheets and plates meet the necessary standards.

What are the common applications of gauge steel thickness?

+Gauge steel thickness is critical in various industries, including construction, manufacturing, and engineering. Common applications include building construction, automotive manufacturing, and aerospace engineering, where thickness affects performance, safety, and durability.